Communications of the ACM

Bypassing Rare Minerals

The U.S. Department of Energy compares the criticality of clean energy efforts of rare metals.

Credit: U.S. Department of Energy

Several years ago, there was a worldwide panic over the Chinese having a veritable stranglehold on the rare metals needed to make electronics, and the need to develop alternative mines in other countries. The U.S. Congress got involved, devoting precious resources to finding new sources of rare metals to keep us from becoming dependent on China.

To make matters worse, China starting setting quotas for its exports of rare metals, to ensure its fledgling homegrown manufacturing operations were adequately supplied before any rare metals were exported to "competitors" around the world (but especially in Japan, China's arch-rival).

Samsung, for one, has resorted to mining its own rare minerals. Unfortunately, try as they may, the U.S., Japan, Europe, Australia, and other "pollution-conscious" countries of the world have not found significant economical alternatives to the dirty, environmentally unfriendly, strip-mining practice commonly used in China.

"Rare earth mining and processing has proven to be a very dirty business in the past, with pollution, including radioactive wastes, a trademark of this industry," said then-ranking member Donna Edwards at a June 2011 meeting of the House Subcommittee on Investigations and Oversight of Science, Space and Technology. "Our work to develop a domestic industry will not ignore the real dangers inherent in rare earth mining."

Unfortunately, in June 2015, the only mining operation the subcommittee could entice into attempting to meet safety standards to mine rare metals in the U.S., Molycorp, filed for bankruptcy after four years of intensive efforts and capitalization.

Frustrated, the U.S., Japan, and European nations have worked to develop alternatives to rare earths.

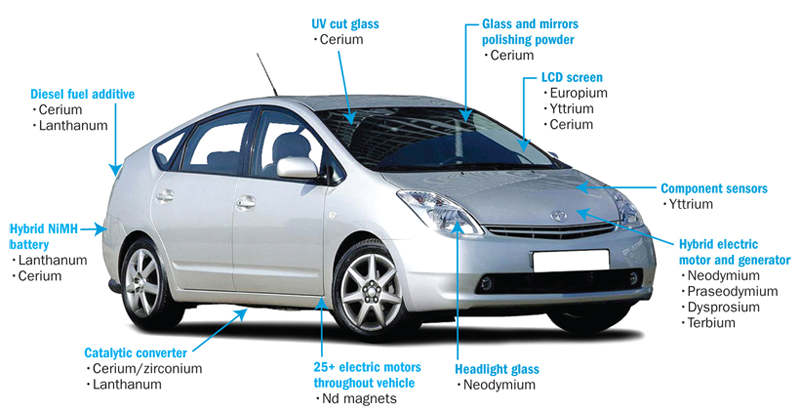

Rare earths, for which China has virtually cornered the market

and is controlling the supply, are used in almost every part

of a modern vehicle. Credit: Toyota

In the context of solid-state lighting (SSL), one of the most important uses of rare earths has been for making phosphors that can glow a desired color. To eliminate the need for rare earths in this application, scientists have invented quantum dots smaller than the wavelength of light desired, causing "quantum confinement" at that wavelength, causing them to glow even brighter than rare-earth phosphors (depending on their size). Researchers worldwide have created multi-color quantum dots in the range of 5 nanometers to 90 nanometers that are cheap to manufacture and require no environmentally unfriendly mining operations. Although these inventions were demonstrated as far back as 1997, they have only recently begun to reach the commercial market--mainly to enhance the brightness and richness of colors on large flat-panel displays.

There is at least one application of rare metals for which it has been hard to find a substitute: replacing the rare metal indium in the massive production of liquid-crystal displays (LCDs), in which indium-tin-oxide (ITO) covers the front surface to form the thin-film transistors (TFTs) that turn "on" pixels. Manufacturers such as France’s Cime Nanotech, Germany’s Clevios, and Taiwan’s Inputek have tried to replace ITO with slurries of carbon nanotubes and graphene, but because they are placed on the front of the LCD, that solution inevitably cuts down on some of the light transmitted, making the LCDs dimmer.

Now a new approach is being proposed by Japanese researchers at the Tokyo Institute of Technology, its Precision and Intelligence Laboratory in Yokohama, and Doshisha University (Kyoto). Their idea, as detailed in their paper "Control of liquid crystal molecular orientation using ultrasound vibration," eliminates front-side TFTs altogether, leaving the glass crystal-clear, and instead using targeted ultrasound from the side to activate pixels. The researchers claim the LCD will be even brighter than those manufactured today (since even ITO dims an LCD somewhat), plus they will be cheaper without the expensive ITO material.

The researchers demonstrated the concept with a prototype that uses two off-the-shelf ultrasonic emitters for a two-pixel proof-of-concept display; by using the ultrasonic transducers to introduce flexural vibration modes (acoustic fields) at each pixel location, forcing its liquid crystal layer's molecular orientation to change, thus affecting its light transmission. "By modulating the ultrasonic driving frequency and voltage, the spatial distribution of the molecular orientation of the liquid crystals could be controlled," said the researchers.

In more detail, the researchers were able to control the thickness of the liquid-crystal material at each pixel site; the thicker it is, the less light is let through, allowing them to control each pixel’s light transmission with no moving parts, just the induced acoustic fields.

To facilitate the formation of the acoustic fields, the outside of the LCD was coated with an ultra-transparent film of polyamide, with the glass LCD panels held apart by 5-, 10- and 25-micron microspheres embedded in epoxy around the edges. The ultrasonic piezoeletric lead-zirconate titanate (PZT) transducers polarized the thickness direction of the sandwiched liquid crystal between the two panes from its edges. The ultrasonic frequencies used ranged from 59kHz to 189kHz, far above the range of human hearing.

"Ultrasonics has created new possibilities for ultra-high-resolution LCDs, especially where clarity and high speed are a factor," said Rick Doherty, research director at Envisioneering, Seaford, NY. "They could be resolution-independent and offer speeds much higher than ITO, potentially greater than 240 hertz, making them perfect for specialty markets like medial imaging and for small cells with very bright light, such as theater projectors. In the long term, ultrasonics could also migrate to high-end flat panel displays."

R. Colin Johnson is a Kyoto Prize Fellow who has worked as a technology journalist for two decades.

No entries found